2020 High quality Spring Leaf - SUP steel auto parts truck light leaf spring – Jiachuang Detail:

This spring assy are widely used in Russia for light duty truck .

Spring Measurements Specs

Totally 6 blades , 1-2 blade Width(mm)*Thickness(mm): 60*9, 3-6 blade Width(mm)*Thickness(mm): 60*10, Eye to Eye Measurement 1146 mm (Free Length Measurement),Tolerance range within ±3mm . Free Arch Measurement (see picture) 106mm,Tolerance range within ±5mm . we also can provide the bushings as long as customer provide the bushings dimensions .

All datas are obtained by measuring the new produce product .

We have full range material stock:width 40mm-150mm,thickness 5mm-60mm,material grade SUP9, SUP11A , 55Cr3, SAE5160H , 50CrVA , 51CrV4 , 52CrMoV4 .

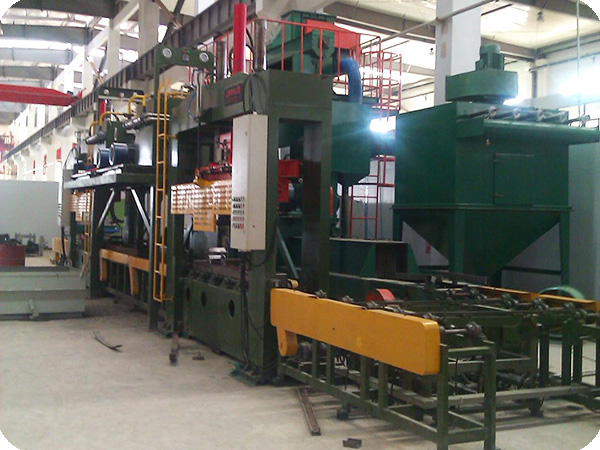

Our products high quality control by the advanced production line :automatic eye rolling machine , automatic queching machine,automatic parabolic machine .

We are in a good position not only to supply you high quality and competitive price , but also the excellent after sales service,Well-trained engineers will offer you any technical supports .

We got ISO9001 certification,our product acquired goods feedbacks from our customers .

Small trial orders can be accepted, sample is available.

We will provide the technical drawings to the customer to check all the details, We have a professional quality inspection section that will inspect each product before shipment and provide the inspection report to the customer . We also can help customers arrange all matters for the shipment delivery .

Key Points Keep The High Quality

| 1) Raw matrail . |

| Thickness less than 20mm. we choose SUP9/55Cr3/SAE5160H as the product material |

| Thickness from 20-30mm. wE choose SUP11A/50CrVA |

| Thickness more than 30mm. We choose 51CrV4 as the raw material |

| Thickness more than 50mm. We choose 52CrMoV4 as the raw material |

| 2) Quchenging Process |

| We strickly controled the steel temeprure around 800 degree. |

| we swing the spring in the qenching oil among 10 seconds according to the spring thickness. |

| 3)Shot Peening. |

| Each assmembing spring set under stress peening . |

| Fatigue test can reach over 150000 cycus |

| 4) Painting |

| Each leaf under cataphoresis painting. |

| Salt spray testing reach 500hours |

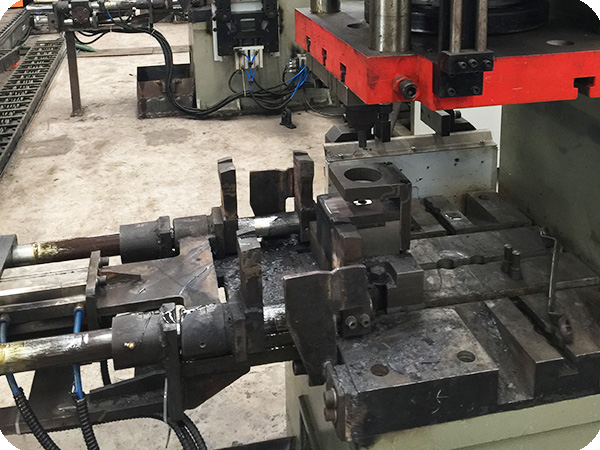

Production Process

1.Material Cutting

4.Edge Cutting

7.Stress Peening

2.Punching

5.Quenching

8.Assembling

3.Eye Rolling

6.Tempering

9.Painting

FAQ

Q1: What type of leaf spring could you produce ?

A: We can produce most kinds of springs in the market. especially on the parabolic springs.

Q2: What material could you supply for leaf spring?

A: Our material grade should be SUP9/SUP9A /SUP11A/51CrV4 /52CrMoV4/ even 55Cr3 and SAE5160H as well .

Q3: How long will be your delivery time?

A: 20-40days. If material stock enough around 20days. if not,would be 40days

Q4: What payment terms are acceptable?

A: TT and LC at sight

Q5: What is the packing?

A: No fumigation wooden pallet . we also can pack according to whatever you request if reasonable.

Q6:How about the surface finishing ?

A : electrophoresis coating (black,red,gray,or as customer’s requests )

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the power by quality". Our enterprise has strived to establish a remarkably efficient and stable team team and explored an effective excellent control system for 2020 High quality Spring Leaf - SUP steel auto parts truck light leaf spring – Jiachuang, The product will supply to all over the world, such as: Barcelona, Bhutan, Mexico, For more than ten years experience in this filed, our company has gained high reputation from home and abroad. So we welcome friends from all over the world to come and contact us, not only for business, but also for friendship.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.

-

Manufacturing Companies for Upper Control Arm B...

-

OEM China Wire Rope U Bolt Clamp - Auto parts ...

-

PriceList for U Hook With Bolt - IVECO truck p...

-

High Quality for U Shape Bolt - SCANIA truck p...

-

Lowest Price for HD72 leaf spring - Auto part ...

-

Factory Supply Bimetal Bushing - Toyota Suspen...