Best quality Short Leaf Springs - 24T Heavy duty truck suspension part leaf spring – Jiachuang Detail:

This spring assy are widely used in Middle East for heavy duty truck .

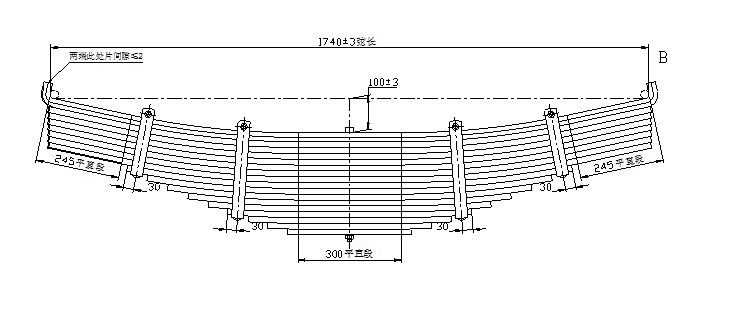

Spring Measurements Specs

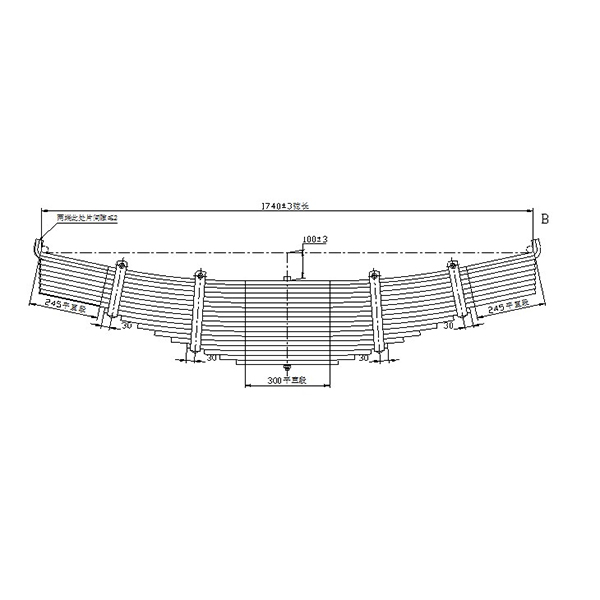

Totally 18 blades , 1-2 blade Width(mm)*Thickness(mm): 90*13, 3-18 blade Width(mm)*Thickness(mm): 90*17, end to end Measurement 1740 mm (Free Length Measurement),Tolerance range within ±3mm .

Free Arch Measurement (see picture) 100mm,Tolerance range within ±3mm .

All datas are obtained by measuring the new produce product .

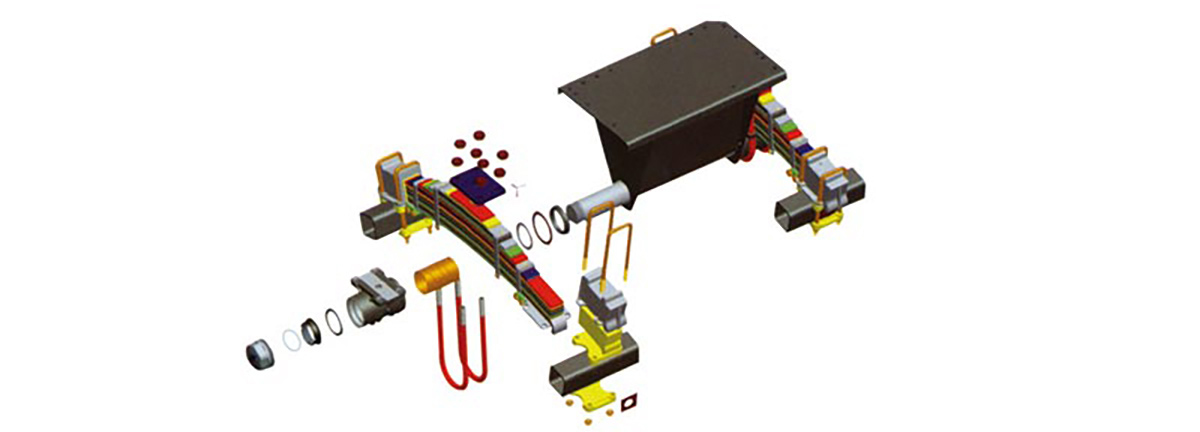

Bogie Suspension System

In order to improve the vertical vibration ride comfort of high speed trains in operation for Shinkansen, the measures to reduce the resilient vibration of car-bodies are applied, and the design method of the bogie suspension system is given out.

Advantage

01.No Rust problem + Perfect looking

Method:

>> Single leaf by electrophoretic painting(Optional)

>> Sembling spring by electrostatic painting(Optional)

Benefits for customers

>> Salt spray testing > 500 hours beat general industrial level 200 hours,avoid rust possiblity

>> Perfect-looking — uniform painting, complete painting, no scratch

02. Pre shot-peening

Method:

>> Make shot peening under rated capacity

Benefits for customers

>> 180,000 times fatigue life beat general level 150,000 times;

>> bear heavier capacity and use longer time;

03. Pre-pressing and adjust

Method:

>> Make pre-pressing under rated capacity

>> Select camber by computer

Benefits for customers

>> Guarantee reasonable camber and keep smallest tolerance,

>> select out leaf spring whose camber is not qualified

Key Points Keep The High Quality

| 1) Raw matrail . |

| Thickness less than 20mm. we choose SUP9/55Cr3/SAE5160H as the product material |

| Thickness from 20-30mm. wE choose SUP11A/50CrVA |

| Thickness more than 30mm. We choose 51CrV4 as the raw material |

| Thickness more than 50mm. We choose 52CrMoV4 as the raw material |

| 2) Quchenging Process |

| We strickly controled the steel temeprure around 800 degree. |

| we swing the spring in the qenching oil among 10 seconds according to the spring thickness. |

| 3)Shot Peening. |

| Each assmembing spring set under stress peening . |

| Fatigue test can reach over 150000 cycus |

| 4) Painting |

| Each leaf under cataphoresis painting. |

| Salt spray testing reach 500hours |

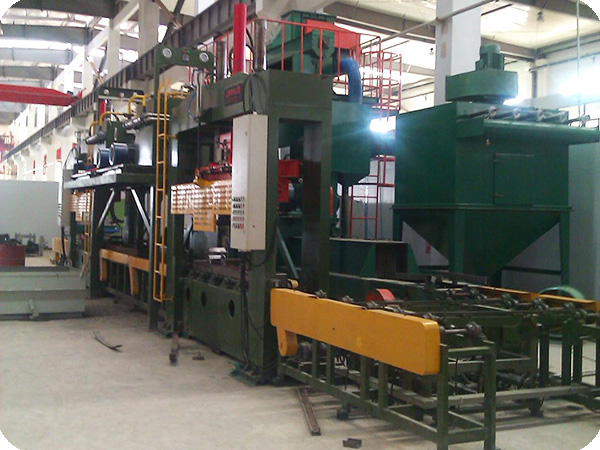

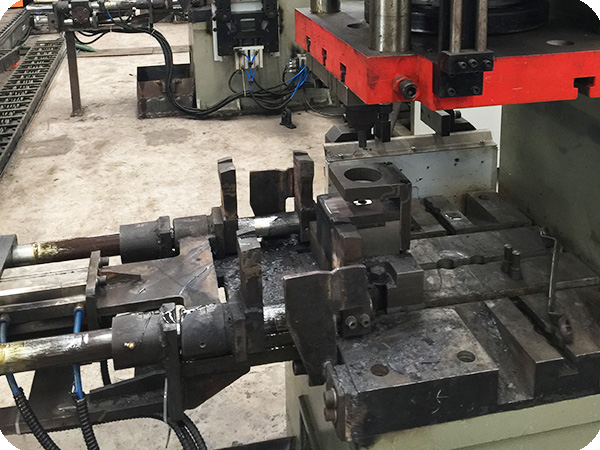

Production Process

1.Material Cutting

4.Edge Cutting

7.Stress Peening

2.Punching

5.Quenching

8.Assembling

3.Eye Rolling

6.Tempering

9.Painting

FAQ

Q1: What type of leaf spring could you produce ?

A: We can produce most kinds of springs in the market. especially on the parabolic springs.

Q2: What material could you supply for leaf spring?

A: Our material grade should be SUP9/SUP9A /SUP11A/51CrV4 /52CrMoV4/ even 55Cr3 and SAE5160H as well .

Q3: How long will be your delivery time?

A: 20-40days. If material stock enough around 20days. if not,would be 40days

Q4: What payment terms are acceptable?

A: TT and LC at sight

Q5: What is the packing?

A: No fumigation wooden pallet . we also can pack according to whatever you request if reasonable.

Q6:How about the surface finishing ?

A : electrophoresis coating (black,red,gray,or as customer’s requests )

Product detail pictures:

Related Product Guide:

We usually believe that one's character decides products' high quality, the details decides products' excellent ,with the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Best quality Short Leaf Springs - 24T Heavy duty truck suspension part leaf spring – Jiachuang, The product will supply to all over the world, such as: Buenos Aires, Dubai, Lithuania, Our company will continue to adhere to the " superior quality, reputable, the user first " principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.

-

Special Price for Copper Suspension Bushings -...

-

OEM/ODM Factory Freightliner Leaf Spring - Pro...

-

China OEM G Body Rear Control Arm Bushings - W...

-

Good Quality U Bolt Dimensions - Trailer suspe...

-

Chinese wholesale Galvanized Trailer Leaf Sprin...

-

Hot sale Factory U Bolt Types - Hexagon nuts f...