Factory making Leaf Spring Front Suspension - OEM 55-031 Trailer part leaf spring for American market – Jiachuang Detail:

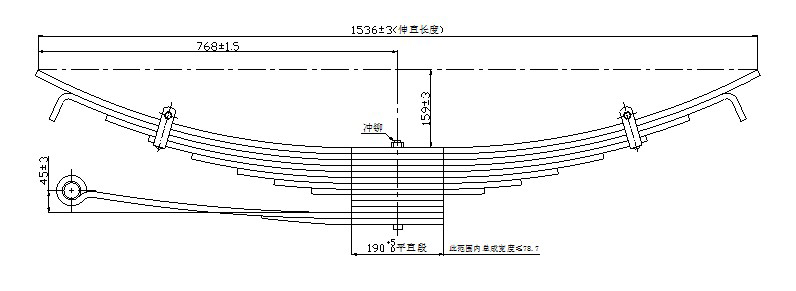

Spring Measurements Specs

Totally 13 blades , the 1st blade Width(mm)*Thickness(mm): 76*13, the 2-13 blade Width(mm)*Thickness(mm): 76*12 , End to End Measurement 1536 mm (Free Length Measurement),Tolerance range within± 3mm . 1pcs biametal bushesØ32*Ø38*74 comes to install spring eyes .

Free Arch Measurement (see picture) 159mm,Tolerance range within ±3mm .

All datas are obtained by measuring the new produce product .

International Trucks

Navistar International Corporation Formerly International Harvester Company is an American Holding company that owns the manufacturer of International brand commercial trucks .

Class 5 : International TerraStar,4300 series .

Class 6 : International DuraStar,4400 series , International Navistar(4600,4700,4900),International Harvester (S-1600,S-1700,S-1800,S-1900,S-2000)

Class 7 : International Navistar (S-2200 short-hood-wide-cab,S-2500 long-hood,S-2600 long hood-set back front axle),International Navistar (8100,8200),DuraStar 7600 series .

Class 8 : ProStar ,9000 series(9100,9200i, 9400i, 9900i , 9900ix),LoneStar,8000 series (8500,8600),TranStar ,PayStar(5500,5600,5900-SFA”SET FRONT AXLE”,5900-SBA”SET BACK AXLE”),WorkStar 7300,7400,7500,7600,7700, DuraStar 4300/4400 6×4 .

International Trucks Leaf Spring Catalogue

|

Part NO. |

ASSY |

W*T(mm) |

Per Weight(kg) |

|

55-031 |

13L |

76*12/13 |

70.1 |

|

55-035 |

14L |

75*13 |

87.9 |

|

55-035HD |

14L |

76*13/15 |

108.8 |

|

55-037 |

4L |

76*9/10 |

16.6 |

|

55-041 |

14L |

76*9/12/13 |

75.8 |

|

55-1197 |

13L |

76*10/12/13 |

76.6 |

|

55-029 |

14L |

76*11/12/13 |

79.9 |

The above is just a small part of our catalogue, if you have demands on other American trucks, like TRA-series, Hendrickson, Freightliner, GMC, MACK, KENWORTH, Please send your inquiry to us , we will provide our best price to you.

Key Points Keep The High Quality

| 1) Raw matrail . |

| Thickness less than 20mm. we choose SUP9/55Cr3/SAE5160H as the product material |

| Thickness from 20-30mm. wE choose SUP11A/50CrVA |

| Thickness more than 30mm. We choose 51CrV4 as the raw material |

| Thickness more than 50mm. We choose 52CrMoV4 as the raw material |

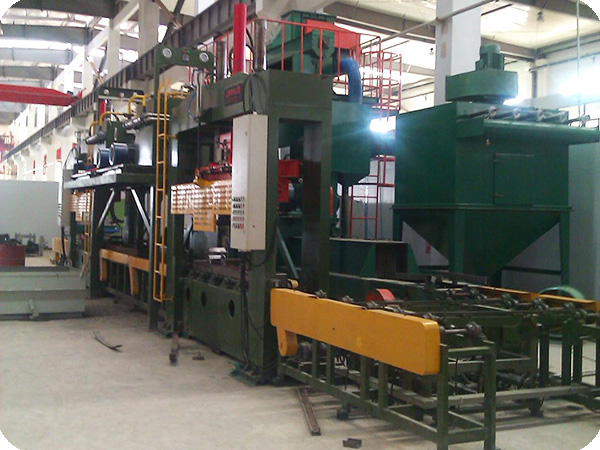

| 2) Quchenging Process |

| We strickly controled the steel temeprure around 800 degree. |

| we swing the spring in the qenching oil among 10 seconds according to the spring thickness. |

| 3)Shot Peening. |

| Each assmembing spring set under stress peening . |

| Fatigue test can reach over 150000 cycus |

| 4) Painting |

| Each leaf under cataphoresis painting. |

| Salt spray testing reach 500hours |

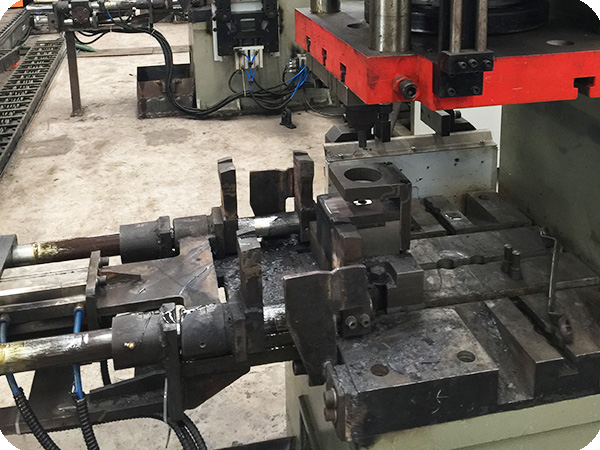

Production Process

1.Material Cutting

4.Edge Cutting

7.Stress Peening

2.Punching

5.Quenching

8.Assembling

3.Eye Rolling

6.Tempering

9.Painting

FAQ

Q1: What type of leaf spring could you produce ?

A: We can produce most kinds of springs in the market. especially on the parabolic springs.

Q2: What material could you supply for leaf spring?

A: Our material grade should be SUP9/SUP9A /SUP11A/51CrV4 /52CrMoV4/ even 55Cr3 and SAE5160H as well .

Q3: How long will be your delivery time?

A: 20-40days. If material stock enough around 20days. if not,would be 40days

Q4: What payment terms are acceptable?

A: TT and LC at sight

Q5: What is the packing?

A: No fumigation wooden pallet . we also can pack according to whatever you request if reasonable.

Q6:How about the surface finishing ?

A : electrophoresis coating (black,red,gray,or as customer’s requests )

Product detail pictures:

Related Product Guide:

We constantly carry out our spirit of ''Innovation bringing advancement, Highly-quality guaranteeing subsistence, Administration selling advantage, Credit rating attracting buyers for Factory making Leaf Spring Front Suspension - OEM 55-031 Trailer part leaf spring for American market – Jiachuang, The product will supply to all over the world, such as: UAE, America, Cape Town, we are fully determined to control the whole supply chain so as to provide quality products at competitive price in a timely manner. We are keeping up with the advanced techniques, growing through creating more values for our clients and society.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.

-

Factory making Big U Bolts - Auto parts fasten...

-

OEM Customized Zinc Plated U Bolt - Grade 10.9...

-

Massive Selection for VOLVO FH13 Leaf Spring -...

-

Fixed Competitive Price ISUZU NRR Leaf Spring -...

-

Super Lowest Price Hino U Bolt - u shaped bolt...

-

PriceList for Iron Bushing - Good Quality Toyo...