Factory Promotional Chevy Rear Leaf Springs - HPF5 light truck leaf spring for Russia market – Jiachuang Detail:

This spring assy are widely used in Russia for light duty truck .

Spring Measurements Specs

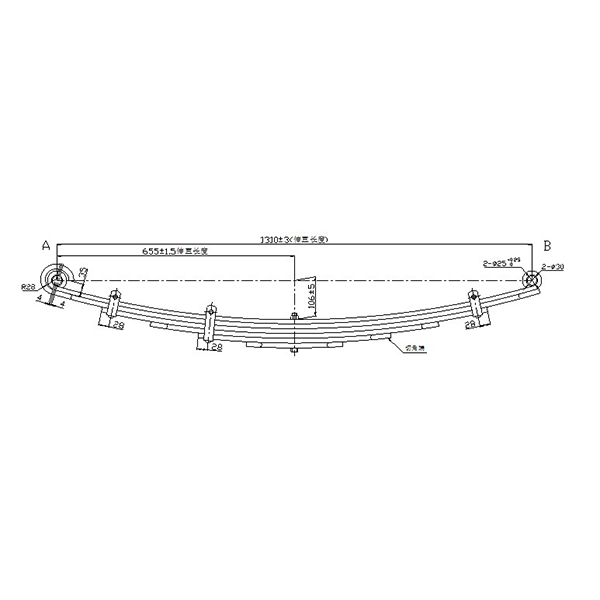

Totally 6 blades , the 1st blade Width(mm)*Thickness(mm): 70*11, 2-6 blade Width(mm)*Thickness(mm): 70*13, Eye to Eye Measurement 1310 mm (Free Length Measurement),Tolerance range within ±3mm . 2pcs biametal bushesØ25*Ø30*68 comes to install spring eyes .

Free Arch Measurement (see picture) 106mm,Tolerance range within ±5mm .

All datas are obtained by measuring the new produce product .

We have full range material stock:width 40mm-150mm,thickness 5mm-60mm,material grade SUP9, SUP11A , 55Cr3, SAE5160H , 50CrVA , 51CrV4 , 52CrMoV4 .

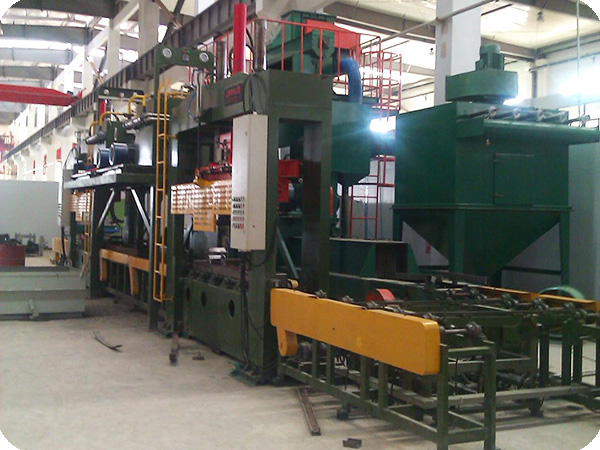

Our products high quality control by the advanced production line :automatic eye rolling machine , automatic queching machine,automatic parabolic machine .

We are in a good position not only to supply you high quality and competitive price , but also the excellent after sales service,Well-trained engineers will offer you any technical supports .

We got ISO9001 certification,our product acquired goods feedbacks from our customers .

Small trial orders can be accepted, sample is available.

We will provide the technical drawings to the customer to check all the details, We have a professional quality inspection section that will inspect each product before shipment and provide the inspection report to the customer . We also can help customers arrange all matters for the shipment delivery .

Key Points Keep The High Quality

| 1) Raw matrail . |

| Thickness less than 20mm. we choose SUP9/55Cr3/SAE5160H as the product material |

| Thickness from 20-30mm. wE choose SUP11A/50CrVA |

| Thickness more than 30mm. We choose 51CrV4 as the raw material |

| Thickness more than 50mm. We choose 52CrMoV4 as the raw material |

| 2) Quchenging Process |

| We strickly controled the steel temeprure around 800 degree. |

| we swing the spring in the qenching oil among 10 seconds according to the spring thickness. |

| 3)Shot Peening. |

| Each assmembing spring set under stress peening . |

| Fatigue test can reach over 150000 cycus |

| 4) Painting |

| Each leaf under cataphoresis painting. |

| Salt spray testing reach 500hours |

Production Process

1.Material Cutting

4.Edge Cutting

7.Stress Peening

2.Punching

5.Quenching

8.Assembling

3.Eye Rolling

6.Tempering

9.Painting

FAQ

Q1: What type of leaf spring could you produce ?

A: We can produce most kinds of springs in the market. especially on the parabolic springs.

Q2: What material could you supply for leaf spring?

A: Our material grade should be SUP9/SUP9A /SUP11A/51CrV4 /52CrMoV4/ even 55Cr3 and SAE5160H as well .

Q3: How long will be your delivery time?

A: 20-40days. If material stock enough around 20days. if not,would be 40days

Q4: What payment terms are acceptable?

A: TT and LC at sight

Q5: What is the packing?

A: No fumigation wooden pallet . we also can pack according to whatever you request if reasonable.

Q6:How about the surface finishing ?

A : electrophoresis coating (black,red,gray,or as customer’s requests )

Product detail pictures:

Related Product Guide:

Our primary intention should be to offer our clientele a serious and responsible enterprise relationship, delivering personalized attention to all of them for Factory Promotional Chevy Rear Leaf Springs - HPF5 light truck leaf spring for Russia market – Jiachuang, The product will supply to all over the world, such as: Brunei, Montpellier, Cannes, We have sufficient experience in producing products according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.

-

China New Product Mercedez Benz 2420/2422 Leaf ...

-

China Manufacturer for Leaf Spring U Bolt Plate...

-

Wholesale Anchor U Bolt - BPW truck part wheel...

-

Bottom price Plastic Coated U Bolts - square t...

-

Renewable Design for ISUZU NQR Leaf spring - T...

-

Hot New Products Standard Thread U Bolt - Auto...