OEM Manufacturer Scania Leaf Spring - OEM 1-51130-961-0 truck parabolic leaf spring for ISUZU – Jiachuang Detail:

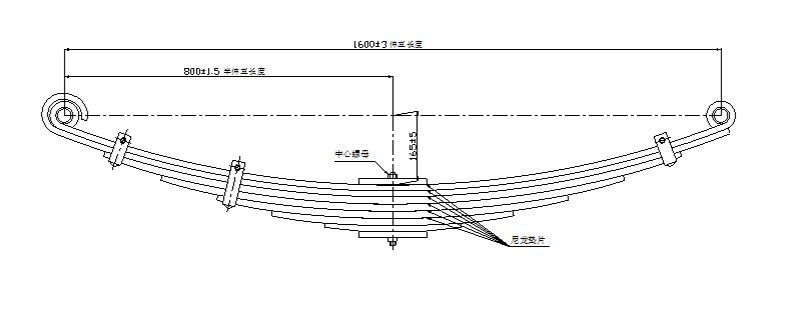

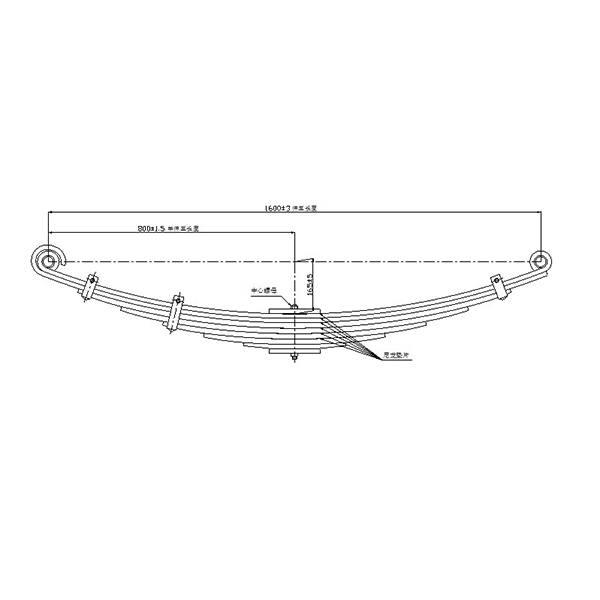

Spring Measurements Specs

7 Blades + 2pcs plates(bottom and top) ,1-2 blade Width(mm)*Thickness(mm) 80*14 ,3-6 blade Width(mm)*Thickness(mm) 80*17 , the 7th blade Width(mm)*Thickness(mm) 80*14

Eye to Eye Measurement 1600mm (Free Length Measurement),Tolerance range within ±3 mm .

Free Arch Measurement (see picture) 165mm,Tolerance range within ±5mm .ØOD 40mm bushings come installed in the spring eyes .all datas comes out by measuring new produce product

Isuzu Leaf Spring Catalogue

| NO. |

PART NO. |

SPEC. |

Weight/KG |

Used For |

|

1 |

1-51130-245-0 FA |

80*14/12 |

77.8 |

ISUZU CXZ |

|

2 |

1-51340-010-0 HA |

80*10/11 |

35.8 |

ISUZU JCR FORWORD CONTROL |

|

3 |

51310-7800 RA |

90*20 |

118.6 |

ISUZU SPZ450 |

|

4 |

8-94101-345-0 FA |

70*9 |

26.4 |

ISUZU NPR 59 |

|

5 |

8-94118-505-1 RA |

70*10/11 |

28.5 |

ISUZU NPR 59 |

|

6 |

8-94118-505-1 HA |

70*10 |

18.7 |

ISUZU NPR 59 |

|

7 |

8-94343-082-M FA |

60*9 |

17.7 |

ISUZU NHR55E MTB(RH) |

|

8 |

8-94343-130-0 RA |

70*11/18 |

31.6 |

ISUZU NHR |

|

9 |

TD50M3 RA |

100*12 |

112 |

ISUZU TU-50 |

|

10 |

1-51130-245-0 FA |

80*14/12 |

77.8 |

ISUZU CXZ |

|

11 |

227-M FA |

70*18/7 |

28 |

ISUZU NPR66P |

|

12 |

8-94343-132-0 RA |

70*10/9/16 |

31.8 |

ISUZU NHR55E |

|

13 |

8-97092-445-1 FA |

70*9/8 |

24.2 |

ISUZU NPR66L |

|

14 |

1-51300-333-2 RA |

80*13 |

58.2 |

ISUZU FTR 12H |

|

15 |

1-51300-333-2 HA |

80*13/6 |

35.4 |

ISUZU FTR 12H |

|

16 |

8-97070-508-M RA |

70*11 |

29 |

ISUZU NKR55L |

|

17 |

8-97070-508-M HA |

70*9 |

16.7 |

ISUZU NKR55L |

|

18 |

1-51110-530-5 FA |

80*13/14/15/18 |

62.4 |

ISUZU FTR 12H |

|

19 |

8-94427-020-0 FA |

70*9 |

28.2 |

ISUZU NPR |

|

20 |

8-9444-074 RA |

70*9/18 |

27.6 |

ISUZU NHR |

|

21 |

8-97092-450-M FA |

70*9 |

27 |

MTB 170 PB |

|

22 |

1-51130-277B |

80*12/14 |

79.4 |

|

|

23 |

1-51310-398A-F |

80*12 |

62.2 |

|

|

24 |

8-98001-543-1 |

70*11/20 |

25.6 |

|

|

25 |

8-97122-382-0 |

70*10/12/13 |

59.4 |

|

|

26 |

8-97096-544-2 |

70*8/10/11 |

32.9 |

ISUZU NPR/NQR-71/75 |

|

27 |

1-5110-786-A |

80*10/12/14 |

65.6 |

|

|

28 |

ISZ 8-97356-160 ASSY |

60*6/7/11/13 |

19.1 |

|

|

29 |

8-97092-449-FA |

70*9 |

26.2 |

|

|

30 |

8-97260-335-0 |

60*8/9 |

26.1 |

|

|

31 |

8-97073-224M-RA |

70*11 |

28.8 |

|

|

32 |

8-97092-445/6M FA |

70*9 |

24.4 |

|

|

33 |

IS-159 (M3) |

70*9*1270 |

6.28 |

ISUZU FRONT |

|

34 |

IS-159 (M5) |

70*9*1180 |

5.84 |

ISUZU FRONT |

|

35 |

IS-159 (M7) |

70*9*930 |

4.6 |

ISUZU FRONT |

|

36 |

IS-262 (H2) |

70*10*850 |

4.67 |

ISUZU AUX |

|

37 |

IS-262 (M2A) |

70*11*1300 |

7.86 |

ISUZU REAR |

|

38 |

IS-277(M1) |

80*12*1450 |

13.29 |

ISUZU FRONT |

|

39 |

IS-315 (M2A) |

60*7*1200 |

3.96 |

ISUZU REAR |

|

40 |

IS-484 (M1) |

80*16*1330 |

13.36 |

ISUZU REAR |

|

41 |

IS-841 (M2A) |

60*6*1090 |

2.99 |

ISUZU REAR |

|

42 |

IS-1346 (M2A) |

70*9*1140 |

5.64 |

ISUZU FRONT |

|

43 |

IS-2290 (M2A) |

70*11*1250 |

7.56 |

ISUZU REAR |

|

44 |

IS-6267 (M2A) |

60*9*1140 |

4.83 |

ISUZU FRONT |

|

45 |

IS-6298 (H1) |

70*9*970 |

4.8 |

ISUZU AUX |

|

46 |

IS-6298 (M2A) |

70*11*1250 |

7.56 |

ISUZU REAR |

|

47 |

IS-6298 (M2) |

70*11*1250 |

7.89 |

ISUZU REAR |

|

48 |

IS-6859 (M2A) |

60*6*1090 |

2.99 |

ISUZU REAR |

|

49 |

IS-6859 (M3) |

60*6*975 |

2.66 |

ISUZU REAR |

|

50 |

IS-9763 (M2A) |

60*7*1200 |

3.96 |

ISUZU REAR |

|

51 |

IS-841(H1)(48″) |

60*12*1220 |

6.9 |

ISUZU REAR |

|

52 |

IS841(53″) |

60*12*1350 |

7.63 |

ISUZU REAR |

|

53 |

IS-841(40″) |

60*12*1016 |

5.74 |

ISUZU REAR |

|

54 |

IS-841(44”) |

60*12*1120 |

6.33 |

ISUZU REAR |

Key Points Keep The High Quality

| 1) Raw matrail . |

| Thickness less than 20mm. we choose SUP9/55Cr3/SAE5160H as the product material |

| Thickness from 20-30mm. wE choose SUP11A/50CrVA |

| Thickness more than 30mm. We choose 51CrV4 as the raw material |

| Thickness more than 50mm. We choose 52CrMoV4 as the raw material |

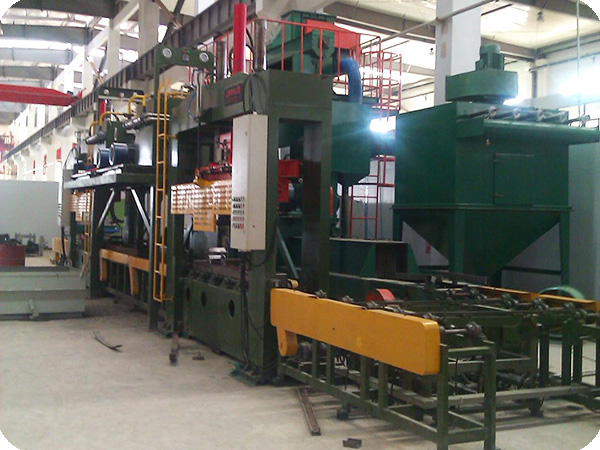

| 2) Quchenging Process |

| We strickly controled the steel temeprure around 800 degree. |

| we swing the spring in the qenching oil among 10 seconds according to the spring thickness. |

| 3)Shot Peening. |

| Each assmembing spring set under stress peening . |

| Fatigue test can reach over 150000 cycus |

| 4) Painting |

| Each leaf under cataphoresis painting. |

| Salt spray testing reach 500hours |

Production Process

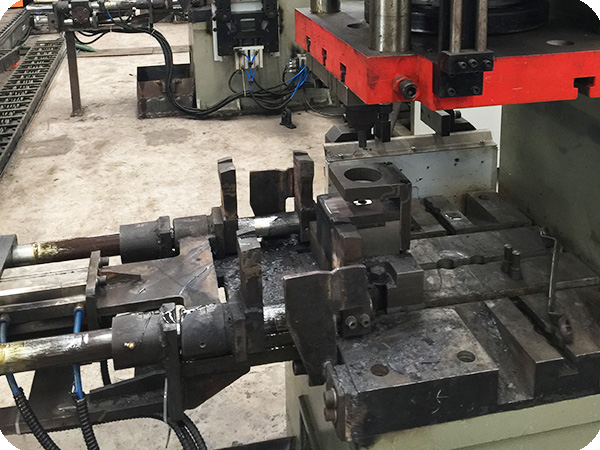

1.Material Cutting

4.Edge Cutting

7.Stress Peening

2.Punching

5.Quenching

8.Assembling

3.Eye Rolling

6.Tempering

9.Painting

FAQ

Q1: What type of leaf spring could you produce ?

A: We can produce most kinds of springs in the market. especially on the parabolic springs.

Q2: What material could you supply for leaf spring?

A: Our material grade should be SUP9/SUP9A /SUP11A/51CrV4 /52CrMoV4/ even 55Cr3 and SAE5160H as well .

Q3: How long will be your delivery time?

A: 20-40days. If material stock enough around 20days. if not,would be 40days

Q4: What payment terms are acceptable?

A: TT and LC at sight

Q5: What is the packing?

A: No fumigation wooden pallet . we also can pack according to whatever you request if reasonable.

Q6:How about the surface finishing ?

A : electrophoresis coating (black,red,gray,or as customer’s requests )

Product detail pictures:

Related Product Guide:

Together with the "Client-Oriented" enterprise philosophy, a arduous good quality control technique, sophisticated producing equipment and a sturdy R&D staff, we generally offer superior quality merchandise, superb solutions and aggressive rates for OEM Manufacturer Scania Leaf Spring - OEM 1-51130-961-0 truck parabolic leaf spring for ISUZU – Jiachuang, The product will supply to all over the world, such as: Venezuela, Turin, Amman, We have the best products and professional sales and technical team.With the development of our company, we are able to provide customers best products, good technical support, perfect after-sales service.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.