OEM Supply SAF-Holland 3155102501 air link - OEM 1-51130-961-0 truck parabolic leaf spring for ISUZU – Jiachuang Detail:

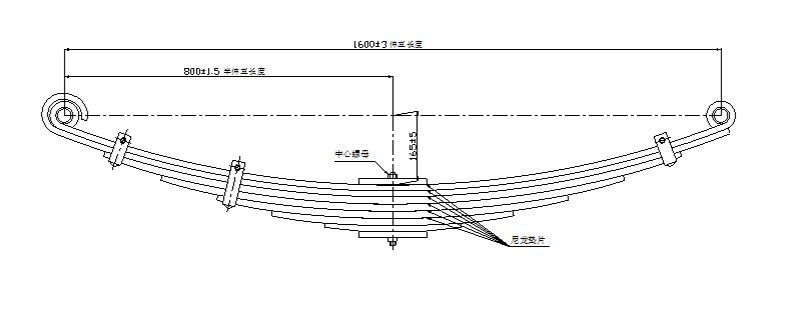

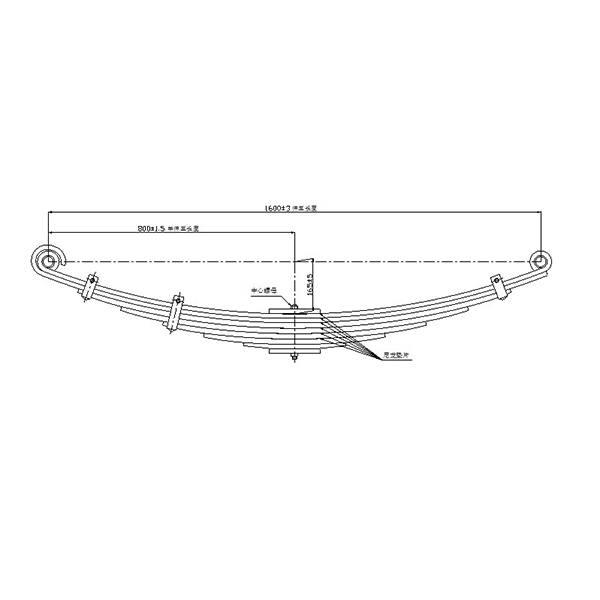

Spring Measurements Specs

7 Blades + 2pcs plates(bottom and top) ,1-2 blade Width(mm)*Thickness(mm) 80*14 ,3-6 blade Width(mm)*Thickness(mm) 80*17 , the 7th blade Width(mm)*Thickness(mm) 80*14

Eye to Eye Measurement 1600mm (Free Length Measurement),Tolerance range within ±3 mm .

Free Arch Measurement (see picture) 165mm,Tolerance range within ±5mm .ØOD 40mm bushings come installed in the spring eyes .all datas comes out by measuring new produce product

Isuzu Leaf Spring Catalogue

| NO. |

PART NO. |

SPEC. |

Weight/KG |

Used For |

|

1 |

1-51130-245-0 FA |

80*14/12 |

77.8 |

ISUZU CXZ |

|

2 |

1-51340-010-0 HA |

80*10/11 |

35.8 |

ISUZU JCR FORWORD CONTROL |

|

3 |

51310-7800 RA |

90*20 |

118.6 |

ISUZU SPZ450 |

|

4 |

8-94101-345-0 FA |

70*9 |

26.4 |

ISUZU NPR 59 |

|

5 |

8-94118-505-1 RA |

70*10/11 |

28.5 |

ISUZU NPR 59 |

|

6 |

8-94118-505-1 HA |

70*10 |

18.7 |

ISUZU NPR 59 |

|

7 |

8-94343-082-M FA |

60*9 |

17.7 |

ISUZU NHR55E MTB(RH) |

|

8 |

8-94343-130-0 RA |

70*11/18 |

31.6 |

ISUZU NHR |

|

9 |

TD50M3 RA |

100*12 |

112 |

ISUZU TU-50 |

|

10 |

1-51130-245-0 FA |

80*14/12 |

77.8 |

ISUZU CXZ |

|

11 |

227-M FA |

70*18/7 |

28 |

ISUZU NPR66P |

|

12 |

8-94343-132-0 RA |

70*10/9/16 |

31.8 |

ISUZU NHR55E |

|

13 |

8-97092-445-1 FA |

70*9/8 |

24.2 |

ISUZU NPR66L |

|

14 |

1-51300-333-2 RA |

80*13 |

58.2 |

ISUZU FTR 12H |

|

15 |

1-51300-333-2 HA |

80*13/6 |

35.4 |

ISUZU FTR 12H |

|

16 |

8-97070-508-M RA |

70*11 |

29 |

ISUZU NKR55L |

|

17 |

8-97070-508-M HA |

70*9 |

16.7 |

ISUZU NKR55L |

|

18 |

1-51110-530-5 FA |

80*13/14/15/18 |

62.4 |

ISUZU FTR 12H |

|

19 |

8-94427-020-0 FA |

70*9 |

28.2 |

ISUZU NPR |

|

20 |

8-9444-074 RA |

70*9/18 |

27.6 |

ISUZU NHR |

|

21 |

8-97092-450-M FA |

70*9 |

27 |

MTB 170 PB |

|

22 |

1-51130-277B |

80*12/14 |

79.4 |

|

|

23 |

1-51310-398A-F |

80*12 |

62.2 |

|

|

24 |

8-98001-543-1 |

70*11/20 |

25.6 |

|

|

25 |

8-97122-382-0 |

70*10/12/13 |

59.4 |

|

|

26 |

8-97096-544-2 |

70*8/10/11 |

32.9 |

ISUZU NPR/NQR-71/75 |

|

27 |

1-5110-786-A |

80*10/12/14 |

65.6 |

|

|

28 |

ISZ 8-97356-160 ASSY |

60*6/7/11/13 |

19.1 |

|

|

29 |

8-97092-449-FA |

70*9 |

26.2 |

|

|

30 |

8-97260-335-0 |

60*8/9 |

26.1 |

|

|

31 |

8-97073-224M-RA |

70*11 |

28.8 |

|

|

32 |

8-97092-445/6M FA |

70*9 |

24.4 |

|

|

33 |

IS-159 (M3) |

70*9*1270 |

6.28 |

ISUZU FRONT |

|

34 |

IS-159 (M5) |

70*9*1180 |

5.84 |

ISUZU FRONT |

|

35 |

IS-159 (M7) |

70*9*930 |

4.6 |

ISUZU FRONT |

|

36 |

IS-262 (H2) |

70*10*850 |

4.67 |

ISUZU AUX |

|

37 |

IS-262 (M2A) |

70*11*1300 |

7.86 |

ISUZU REAR |

|

38 |

IS-277(M1) |

80*12*1450 |

13.29 |

ISUZU FRONT |

|

39 |

IS-315 (M2A) |

60*7*1200 |

3.96 |

ISUZU REAR |

|

40 |

IS-484 (M1) |

80*16*1330 |

13.36 |

ISUZU REAR |

|

41 |

IS-841 (M2A) |

60*6*1090 |

2.99 |

ISUZU REAR |

|

42 |

IS-1346 (M2A) |

70*9*1140 |

5.64 |

ISUZU FRONT |

|

43 |

IS-2290 (M2A) |

70*11*1250 |

7.56 |

ISUZU REAR |

|

44 |

IS-6267 (M2A) |

60*9*1140 |

4.83 |

ISUZU FRONT |

|

45 |

IS-6298 (H1) |

70*9*970 |

4.8 |

ISUZU AUX |

|

46 |

IS-6298 (M2A) |

70*11*1250 |

7.56 |

ISUZU REAR |

|

47 |

IS-6298 (M2) |

70*11*1250 |

7.89 |

ISUZU REAR |

|

48 |

IS-6859 (M2A) |

60*6*1090 |

2.99 |

ISUZU REAR |

|

49 |

IS-6859 (M3) |

60*6*975 |

2.66 |

ISUZU REAR |

|

50 |

IS-9763 (M2A) |

60*7*1200 |

3.96 |

ISUZU REAR |

|

51 |

IS-841(H1)(48″) |

60*12*1220 |

6.9 |

ISUZU REAR |

|

52 |

IS841(53″) |

60*12*1350 |

7.63 |

ISUZU REAR |

|

53 |

IS-841(40″) |

60*12*1016 |

5.74 |

ISUZU REAR |

|

54 |

IS-841(44”) |

60*12*1120 |

6.33 |

ISUZU REAR |

Key Points Keep The High Quality

| 1) Raw matrail . |

| Thickness less than 20mm. we choose SUP9/55Cr3/SAE5160H as the product material |

| Thickness from 20-30mm. wE choose SUP11A/50CrVA |

| Thickness more than 30mm. We choose 51CrV4 as the raw material |

| Thickness more than 50mm. We choose 52CrMoV4 as the raw material |

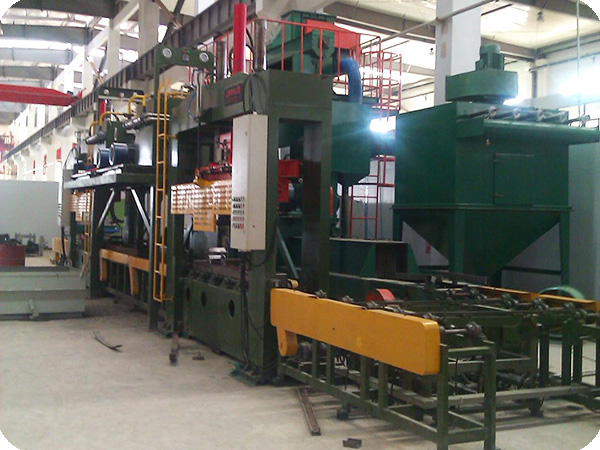

| 2) Quchenging Process |

| We strickly controled the steel temeprure around 800 degree. |

| we swing the spring in the qenching oil among 10 seconds according to the spring thickness. |

| 3)Shot Peening. |

| Each assmembing spring set under stress peening . |

| Fatigue test can reach over 150000 cycus |

| 4) Painting |

| Each leaf under cataphoresis painting. |

| Salt spray testing reach 500hours |

Production Process

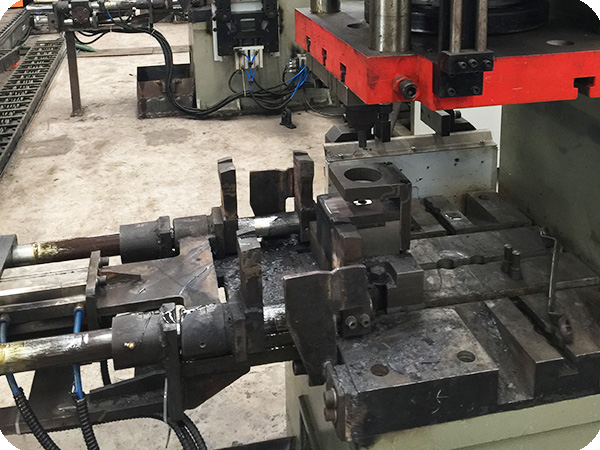

1.Material Cutting

4.Edge Cutting

7.Stress Peening

2.Punching

5.Quenching

8.Assembling

3.Eye Rolling

6.Tempering

9.Painting

FAQ

Q1: What type of leaf spring could you produce ?

A: We can produce most kinds of springs in the market. especially on the parabolic springs.

Q2: What material could you supply for leaf spring?

A: Our material grade should be SUP9/SUP9A /SUP11A/51CrV4 /52CrMoV4/ even 55Cr3 and SAE5160H as well .

Q3: How long will be your delivery time?

A: 20-40days. If material stock enough around 20days. if not,would be 40days

Q4: What payment terms are acceptable?

A: TT and LC at sight

Q5: What is the packing?

A: No fumigation wooden pallet . we also can pack according to whatever you request if reasonable.

Q6:How about the surface finishing ?

A : electrophoresis coating (black,red,gray,or as customer’s requests )

Product detail pictures:

Related Product Guide:

Every single member from our higher effectiveness product sales staff values customers' requires and organization communication for OEM Supply SAF-Holland 3155102501 air link - OEM 1-51130-961-0 truck parabolic leaf spring for ISUZU – Jiachuang, The product will supply to all over the world, such as: Oman, Istanbul, Sydney, Our company has abundant strength and possesses a steady and perfect sales network system. We wish we could establish sound business relationships with all customers from at home and abroad on the basis of mutual benefits.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.

-

Factory Free sample Wide U Bolts - Sample aval...

-

Best quality Arm Bush - Truck suspension compo...

-

China OEM Iveco Leaf Spring - Hot Sale TRA-021...

-

2020 wholesale price Dump Truck Leaf Spring - ...

-

High Performance Rubber Cushioned U Bolt - Tra...

-

factory Outlets for Neoprene Bushings Suspensio...