OEM/ODM Supplier Mack Leaf Spring - OEM 55-031 Trailer part leaf spring for American market – Jiachuang Detail:

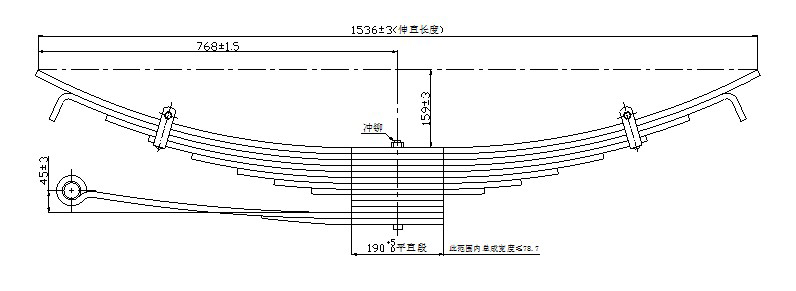

Spring Measurements Specs

Totally 13 blades , the 1st blade Width(mm)*Thickness(mm): 76*13, the 2-13 blade Width(mm)*Thickness(mm): 76*12 , End to End Measurement 1536 mm (Free Length Measurement),Tolerance range within± 3mm . 1pcs biametal bushesØ32*Ø38*74 comes to install spring eyes .

Free Arch Measurement (see picture) 159mm,Tolerance range within ±3mm .

All datas are obtained by measuring the new produce product .

International Trucks

Navistar International Corporation Formerly International Harvester Company is an American Holding company that owns the manufacturer of International brand commercial trucks .

Class 5 : International TerraStar,4300 series .

Class 6 : International DuraStar,4400 series , International Navistar(4600,4700,4900),International Harvester (S-1600,S-1700,S-1800,S-1900,S-2000)

Class 7 : International Navistar (S-2200 short-hood-wide-cab,S-2500 long-hood,S-2600 long hood-set back front axle),International Navistar (8100,8200),DuraStar 7600 series .

Class 8 : ProStar ,9000 series(9100,9200i, 9400i, 9900i , 9900ix),LoneStar,8000 series (8500,8600),TranStar ,PayStar(5500,5600,5900-SFA”SET FRONT AXLE”,5900-SBA”SET BACK AXLE”),WorkStar 7300,7400,7500,7600,7700, DuraStar 4300/4400 6×4 .

International Trucks Leaf Spring Catalogue

|

Part NO. |

ASSY |

W*T(mm) |

Per Weight(kg) |

|

55-031 |

13L |

76*12/13 |

70.1 |

|

55-035 |

14L |

75*13 |

87.9 |

|

55-035HD |

14L |

76*13/15 |

108.8 |

|

55-037 |

4L |

76*9/10 |

16.6 |

|

55-041 |

14L |

76*9/12/13 |

75.8 |

|

55-1197 |

13L |

76*10/12/13 |

76.6 |

|

55-029 |

14L |

76*11/12/13 |

79.9 |

The above is just a small part of our catalogue, if you have demands on other American trucks, like TRA-series, Hendrickson, Freightliner, GMC, MACK, KENWORTH, Please send your inquiry to us , we will provide our best price to you.

Key Points Keep The High Quality

| 1) Raw matrail . |

| Thickness less than 20mm. we choose SUP9/55Cr3/SAE5160H as the product material |

| Thickness from 20-30mm. wE choose SUP11A/50CrVA |

| Thickness more than 30mm. We choose 51CrV4 as the raw material |

| Thickness more than 50mm. We choose 52CrMoV4 as the raw material |

| 2) Quchenging Process |

| We strickly controled the steel temeprure around 800 degree. |

| we swing the spring in the qenching oil among 10 seconds according to the spring thickness. |

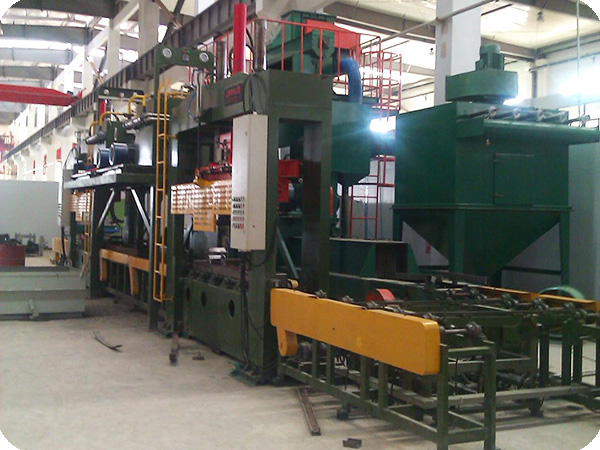

| 3)Shot Peening. |

| Each assmembing spring set under stress peening . |

| Fatigue test can reach over 150000 cycus |

| 4) Painting |

| Each leaf under cataphoresis painting. |

| Salt spray testing reach 500hours |

Production Process

1.Material Cutting

4.Edge Cutting

7.Stress Peening

2.Punching

5.Quenching

8.Assembling

3.Eye Rolling

6.Tempering

9.Painting

FAQ

Q1: What type of leaf spring could you produce ?

A: We can produce most kinds of springs in the market. especially on the parabolic springs.

Q2: What material could you supply for leaf spring?

A: Our material grade should be SUP9/SUP9A /SUP11A/51CrV4 /52CrMoV4/ even 55Cr3 and SAE5160H as well .

Q3: How long will be your delivery time?

A: 20-40days. If material stock enough around 20days. if not,would be 40days

Q4: What payment terms are acceptable?

A: TT and LC at sight

Q5: What is the packing?

A: No fumigation wooden pallet . we also can pack according to whatever you request if reasonable.

Q6:How about the surface finishing ?

A : electrophoresis coating (black,red,gray,or as customer’s requests )

Product detail pictures:

Related Product Guide:

Our primary objective is always to offer our clients a serious and responsible small business relationship, offering personalized attention to all of them for OEM/ODM Supplier Mack Leaf Spring - OEM 55-031 Trailer part leaf spring for American market – Jiachuang, The product will supply to all over the world, such as: Vietnam, Colombia, South Africa, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.

-

China Supplier Chevy Truck Leaf Springs - High...

-

2020 wholesale price Rubber Shock Absorber Bush...

-

Renewable Design for Leaf Spring U Bolts - SCA...

-

Lowest Price for Rear Suspension Rubber Bushing...

-

2020 China New Design Galv U Bolts - Sample av...

-

Free sample for FUSO FK rear leaf spring - OEM...