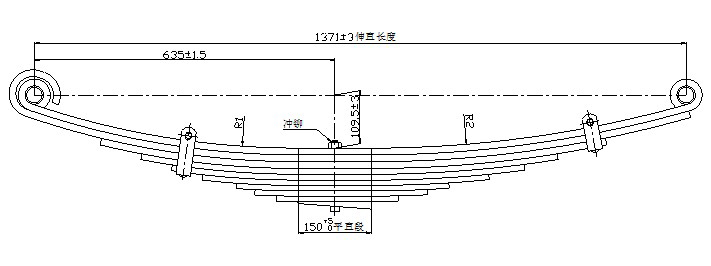

One of Hottest for Chrome Leaf Springs - OEM 43-698 truck part front leaf spring with bushings – Jiachuang Detail:

This spring assy are widely used in American for heavy duty truck .

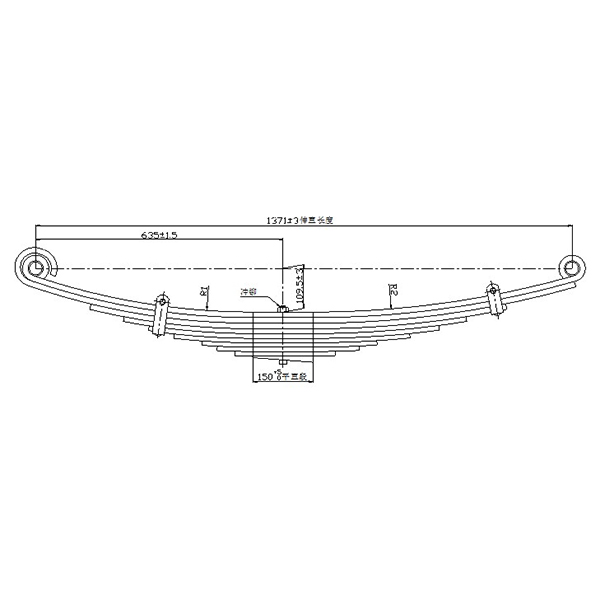

Spring Measurements Specs

Totally 9 blades , 1pc Inclined plate ,1-4 blade Width(mm)*Thickness(mm): 100*14, 5-6 blade Width(mm)*Thickness(mm): 100*13, 7-9 blade 100*11 , Eye to Eye Measurement 1371 mm (Free Length Measurement),Tolerance range within ±3mm . 2pcs biametal bushesØ32*Ø38*98 comes to install spring eyes .

Free Arch Measurement (see picture) 109.5mm,Tolerance range within ±3mm .

All datas are obtained by measuring the new produce product .

|

NO.Leaf |

W&T(mm) |

Length(mm) |

Per Weight(kg) |

Assy Weight(kg) |

|

1 |

100*14 |

635+736 |

18.44 |

82.2 |

|

2 |

100*14 |

635+736 |

17.41 |

|

|

3 |

100*14 |

486+562 |

11.89 |

|

|

4 |

100*14 |

400+460 |

9.45 |

|

|

5 |

100*13 |

336+390 |

7.86 |

|

|

6 |

100*13 |

273+317 |

6.02 |

|

|

7 |

100*11 |

203+235 |

3.78 |

|

|

8 |

100*11 |

165+190 |

3.07 |

|

|

9 |

100*11 |

120+130 |

2.16 |

Ford Trucks Introduce

The Ford F/L-Series are a series of full -size pickup and heavy duty trucks from the Ford Motor Company which has been sold continuously since 1948 till now for F-series and till 1988 for L-series .

Class 1: F-100,F-101,F-102,F-103,F-104,F-105,F-106,F-107,F-108,F-109,F-10N,F-110,F-111.

Class 2: F-112,F-113,F-140,F-141,F-142,F-143,F-150,F-151,F-250,F-250XLT,F-250HD,F250,F251,F252,F253,F254,F255,F256, F257,F258,F259,F260,F261,F262,F263,F264,F265,F266(Note:models produced in 1972-1979:F350,F351,F352,F353,F354,F355,F356,F357,F358,F359)

Class 3 : F-350,F-360

Class 4 : F-450

Class 5 : F-550

Class 6 : F-650

Class 7 : L-600/L-6000 series,L-700/L-7000 series

Class 7 : L-800/L-8000 series,L-900/L-9000 series

Key Points Keep The High Quality

| 1) Raw matrail . |

| Thickness less than 20mm. we choose SUP9/55Cr3/SAE5160H as the product material |

| Thickness from 20-30mm. wE choose SUP11A/50CrVA |

| Thickness more than 30mm. We choose 51CrV4 as the raw material |

| Thickness more than 50mm. We choose 52CrMoV4 as the raw material |

| 2) Quchenging Process |

| We strickly controled the steel temeprure around 800 degree. |

| we swing the spring in the qenching oil among 10 seconds according to the spring thickness. |

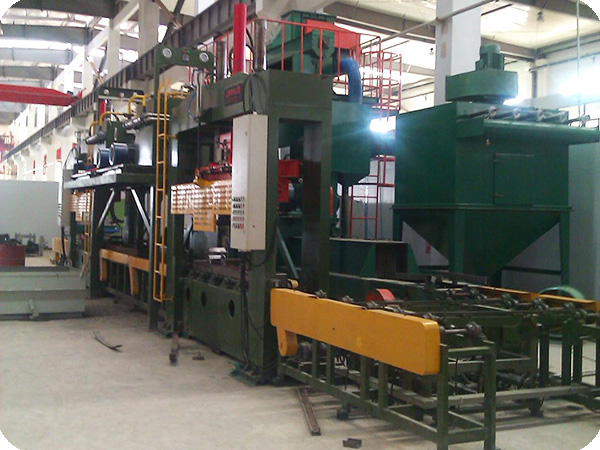

| 3)Shot Peening. |

| Each assmembing spring set under stress peening . |

| Fatigue test can reach over 150000 cycus |

| 4) Painting |

| Each leaf under cataphoresis painting. |

| Salt spray testing reach 500hours |

Production Process

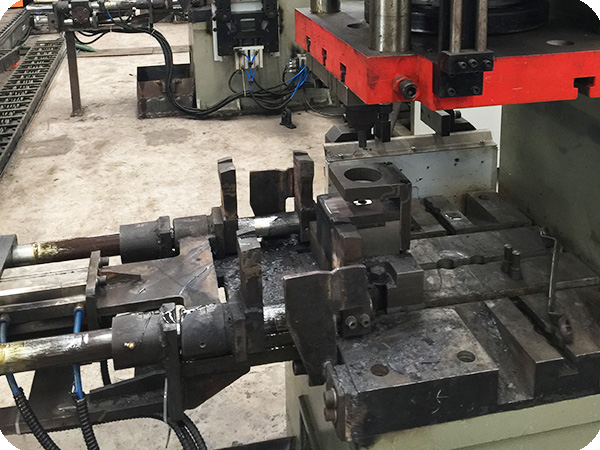

1.Material Cutting

4.Edge Cutting

7.Stress Peening

2.Punching

5.Quenching

8.Assembling

3.Eye Rolling

6.Tempering

9.Painting

FAQ

Q1: What type of leaf spring could you produce ?

A: We can produce most kinds of springs in the market. especially on the parabolic springs.

Q2: What material could you supply for leaf spring?

A: Our material grade should be SUP9/SUP9A /SUP11A/51CrV4 /52CrMoV4/ even 55Cr3 and SAE5160H as well .

Q3: How long will be your delivery time?

A: 20-40days. If material stock enough around 20days. if not,would be 40days

Q4: What payment terms are acceptable?

A: TT and LC at sight

Q5: What is the packing?

A: No fumigation wooden pallet . we also can pack according to whatever you request if reasonable.

Q6:How about the surface finishing ?

A : electrophoresis coating (black,red,gray,or as customer’s requests )

Product detail pictures:

Related Product Guide:

Like a result of ours specialty and repair consciousness, our enterprise has won a superb popularity amid buyers everywhere in the environment for One of Hottest for Chrome Leaf Springs - OEM 43-698 truck part front leaf spring with bushings – Jiachuang, The product will supply to all over the world, such as: Georgia, UK, Angola, Upon today, we have customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.

-

Factory best selling Polyurethane Bushings - T...

-

18 Years Factory ISUZU NKR Leaf Spring - China...

-

Factory wholesale Metric U Bolt - HINO truck p...

-

Reasonable price Galvanized U Bolt Pipe Clamp -...

-

OEM Manufacturer Differential U Bolts - Grade ...

-

Chinese Professional Rubber Mount - China Manu...