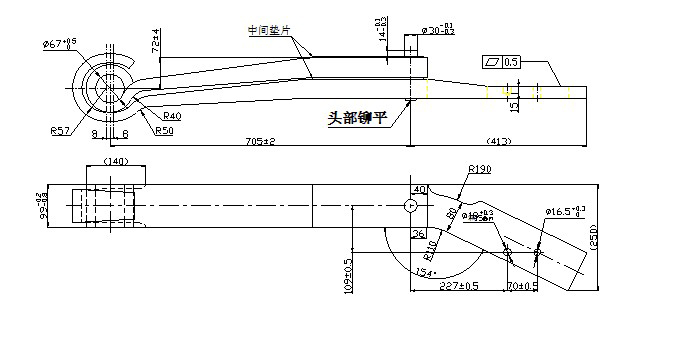

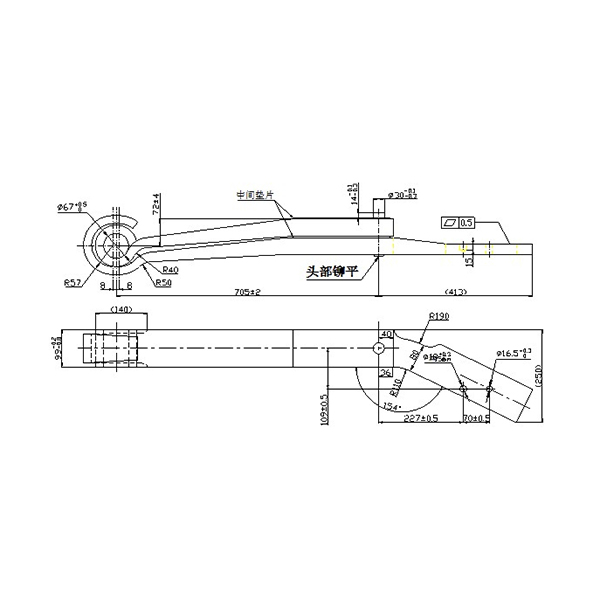

Super Purchasing for Wooden Leaf Spring - 1421060 truck leaf spring air suspension part leaf spring – Jiachuang Detail:

Spring Measurements Specs

Totally 2 blades ,2pcs pad among blades , the 1st blade Width(mm)*Thickness(mm): 100*47, the 2nd blade Width(mm)*Thickness(mm): 100*45, the 1st Measurement 745 mm (Free Length Measurement),the 2nd Measurement 1125 mm (Free Length Measurement) , Tolerance range within ±2mm . 1pc composite bush Ø30*Ø68*121 comes to install spring eyes .

All datas are obtained by measuring the new produce product .

Scania

All Scania models till start of 5-series 2005 onward ,have a simple index system ,the first letter of the far left side(as known as prefix) is the cab type:G(rigidly mounted short,low cab),P(suspended low cab,short or long),R(high cab,short or long),and T(bonneted cab,short or long).Then first one or two digits indicate engine size(e.g.8,11,or 14 liter engine.denotes 82,112/111/110,or 144)and the last number before letter suffixes points out the series which are as followings:0-series(110 and 140 produced 1968-1974),1-series(111 and 141 produced 1974-1981),2-series(82,92,112 and 142 produced 1981-1988)3 series:93,113,143(1987-1995) and finally 4-series(94,114,124,144 and 164 produced 1995-2004).at the end letter suffixes(far right side)M,H,or E,relate to frame/suspension ratings-”medium”,”heavy”,or”extra-heavy”duty.In some models further codes like L,D,C and G were used compared to other to describe the chassistypes .

Finished Products Photos

Key Points Keep The High Quality

| 1) Raw matrail . |

| Thickness less than 20mm. we choose SUP9/55Cr3/SAE5160H as the product material |

| Thickness from 20-30mm. wE choose SUP11A/50CrVA |

| Thickness more than 30mm. We choose 51CrV4 as the raw material |

| Thickness more than 50mm. We choose 52CrMoV4 as the raw material |

| 2) Quchenging Process |

| We strickly controled the steel temeprure around 800 degree. |

| we swing the spring in the qenching oil among 10 seconds according to the spring thickness. |

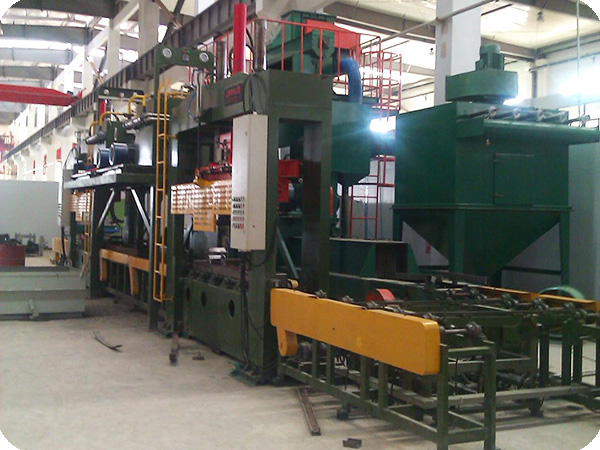

| 3)Shot Peening. |

| Each assmembing spring set under stress peening . |

| Fatigue test can reach over 150000 cycus |

| 4) Painting |

| Each leaf under cataphoresis painting. |

| Salt spray testing reach 500hours |

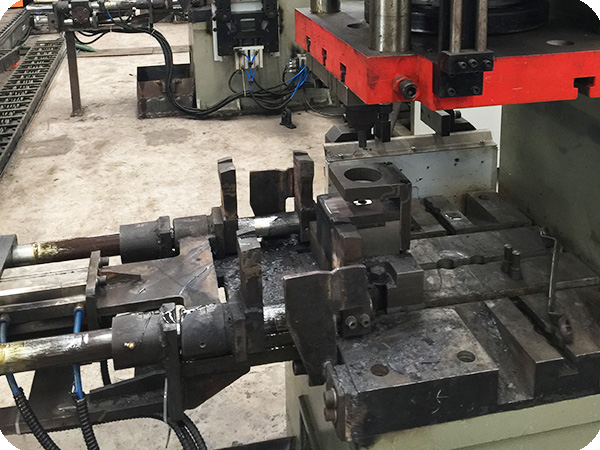

Production Process

1.Material Cutting

4.Edge Cutting

7.Stress Peening

2.Punching

5.Quenching

8.Assembling

3.Eye Rolling

6.Tempering

9.Painting

FAQ

Q1: What type of leaf spring could you produce ?

A: We can produce most kinds of springs in the market. especially on the parabolic springs.

Q2: What material could you supply for leaf spring?

A: Our material grade should be SUP9/SUP9A /SUP11A/51CrV4 /52CrMoV4/ even 55Cr3 and SAE5160H as well .

Q3: How long will be your delivery time?

A: 20-40days. If material stock enough around 20days. if not,would be 40days

Q4: What payment terms are acceptable?

A: TT and LC at sight

Q5: What is the packing?

A: No fumigation wooden pallet . we also can pack according to whatever you request if reasonable.

Q6:How about the surface finishing ?

A : electrophoresis coating (black,red,gray,or as customer’s requests )

Product detail pictures:

Related Product Guide:

We always continually offer you the most conscientious purchaser services, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Super Purchasing for Wooden Leaf Spring - 1421060 truck leaf spring air suspension part leaf spring – Jiachuang, The product will supply to all over the world, such as: Johannesburg, Angola, Brunei, Our company has abundant strength and possesses a steady and perfect sales network system. We wish we could establish sound business relationships with all customers from at home and abroad on the basis of mutual benefits.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!

-

Factory Price For U Bolt Concrete Anchor - Hex...

-

Factory Cheap Hot Ss316 U Bolt - Wheel Bolt fo...

-

Chinese Professional Z Type Leaf Spring - Prof...

-

Fixed Competitive Price Worn Control Arm Bushin...

-

OEM Factory for Trailing Arm Bush - Durable Su...

-

Factory Free sample Arm Bushes Car - We supply...